Breakthrough Robotic Gripper and Myoelectric Integration May Revolutionize Prosthetics

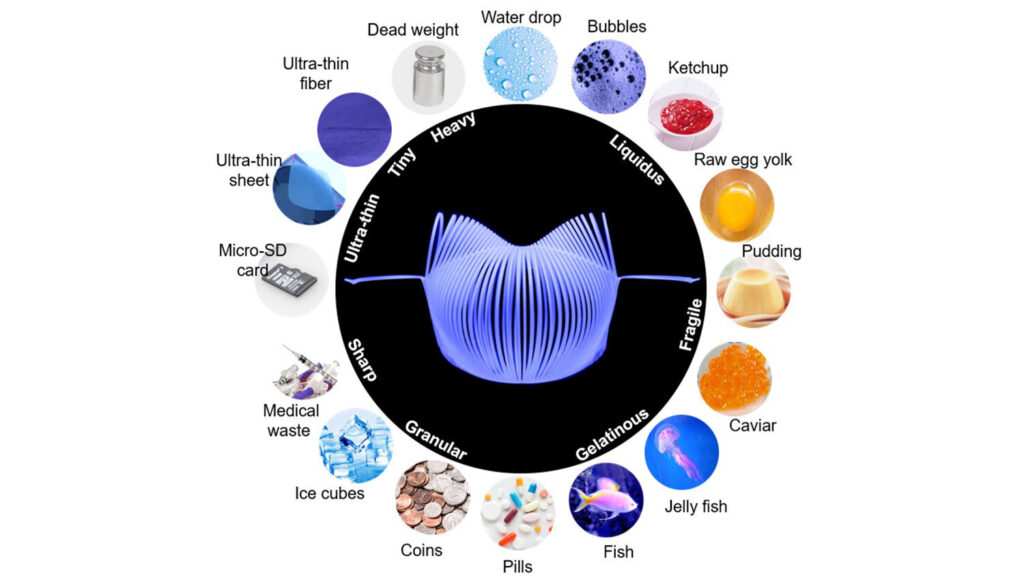

Researchers at North Carolina State University have developed a remarkable robotic gripping device that possesses an impressive combination of features. This gripping device is both delicate enough to lift a drop of water and sturdy enough to handle a weight of up to 6.4 kilograms. It exhibits dexterity by folding cloth and precision by picking up microfilms thinner than a human hair. What’s more, this invention goes beyond manufacturing potential as it’s integrated with technology capable of being controlled by the electrical signals generated by muscles in the forearm, making it a promising tool for use in robotic prosthetics.

Creating such a versatile gripper was a challenge due to the tradeoffs between strength, gentleness, and precision. However, the researchers managed to strike an exceptional balance. The gripper’s design builds upon a prior generation of flexible robotic grippers influenced by kirigami, an art involving cutting and folding two-dimensional materials into three-dimensional shapes. The new version improves upon this concept, refining both the gripper’s structure and its approach trajectory when gripping objects. Its strength is extraordinary, with a payload-to-weight ratio of 16,000, which far surpasses previous records.

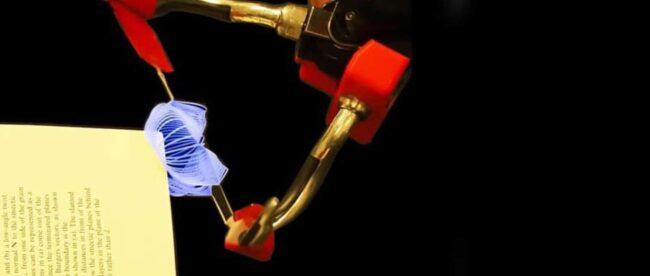

One of the significant advantages of this technology is that its performance stems mainly from its structural design rather than the materials used. This implies that the grippers could be fashioned from biodegradable resources, like sturdy plant leaves, making them suitable for short-term applications such as handling food or biomedical materials. The researchers also managed to integrate the gripping device with a myoelectric prosthetic hand, allowing it to be controlled by muscle activity. While this gripper can’t replace all functions of existing prosthetic hands, it can supplement their capabilities, offering benefits like turning pages of a book or plucking grapes. The team envisions a wide array of applications for this innovation, spanning fields like robotics, food processing, pharmaceuticals, and electronics manufacturing.

Interested in learning more? Head to Nature Communications to read the entire paper in detail.

Promising Implications For Prosthetics

The newly developed robotic gripper, combined with its integration into myoelectric prosthetic technology, holds promising implications for the field of prosthetics. This proof of concept showcases the potential to significantly enhance the functionality of robotic prosthetic devices and address some of the limitations faced by traditional prosthetic solutions.

Firstly, the gripper’s remarkable combination of attributes – strength, gentleness, precision, and dexterity – indicates that it can handle a wide range of tasks and objects. This versatility is particularly valuable in prosthetics, where users often need to interact with various objects and perform delicate tasks. The fact that the gripper’s design allows for an exceptionally high payload-to-weight ratio suggests that it could provide meaningful assistance in tasks that require strength, such as lifting and grasping heavier objects.

Furthermore, the integration of the gripper with myoelectric prosthetic technology marks a significant advancement. By utilizing muscle signals from the forearm to control the gripper, users can achieve more natural and intuitive control over the prosthetic hand. This could greatly improve the user experience and allow individuals with limb loss to regain a higher degree of functional independence.

The potential to supplement existing motor-driven prosthetics without the need for extensive modifications is another noteworthy advantage. This means that individuals who already have robotic prosthetics could enhance their capabilities by simply incorporating this new gripper technology. This expands the range of tasks that can be accomplished with the prosthetic device, making it more versatile and adaptable to real-world scenarios.

In conclusion, the new proof of concept with the robotic gripper and its integration into myoelectric prosthetic systems has the potential to redefine the capabilities of robotic prosthetics. It offers improved strength, precision, and control, enhancing users’ ability to interact with their environment and perform various tasks more effectively. This innovation has the potential to positively impact the lives of amputees and individuals with limb differences by providing them with more functional and versatile prosthetic solutions.

Source: Futurity, North Carolina State University

This blog was written mostly using chatGPT, a potential tool for increased accessibility. Do you think this is an appropriate use of chatGPT? Why or why not? Let me know!

Leave a comment